The energy-efficiency of lighting is determined by the properties of the actual lighting solution used, encompassing the light sources, the luminaires, the realisation of the system, and how the lighting is used. A luminaire’s energy-efficiency depends on the lamp, ballast, and optics used. Use of inappropriate lamps results in a low luminous flux, and the lighting must be designed to compensate for this. The environment too has an impact on the energy-efficiency of the lighting. Surface colours and furniture in the space affect lighting efficacy. In the design of a new building, the lighting’s maintenance factor must be taken into account because the amount of light in the space changes with time on account of lumen depreciation and as surfaces and luminaires accumulate dust and suffer wear and tear. However, the main factor influencing the energy-efficiency of lighting is its control. Taking daylight and the use of the space into account in the control system’s design can result in a significant reduction in energy consumption.

The SFS-EN 12464-1 standard specifies the minimum requirements for the work area, its immediate vicinity, the background, and the room’s walls and ceiling. Specifying the location and size of the work area poses the main challenge for a lighting designer. If these factors are not known, the most energy-efficient solution is to design a lighting system that is easy to adapt. Energy consumption can be reduced by illuminating the right place at the right time. Otherwise, the entire space must be illuminated, which increases the consumption of energy. Each lighting design is unique, and designs that produce good lighting results may vary greatly in their energy-efficiency. It is important to bear in mind that lighting quality should not be compromised in favour of energy-efficiency.

The SFS-EN 15193:2007 standard, on energy performance of buildings and energy requirements for lighting, is aimed at creating uniform requirements and practices for determining the energy requirements for lighting in public buildings. An additional goal is to determine calculation methods for evaluation of the energy consumption of a building’s indoor lighting by means of a lighting energy numeric indicator (LENI). The LENI index can be determined either through measurements or by calculation. The calculations may be performed via either a quick method or a comprehensive method. The standard also offers instructions for measuring the energy used by lighting groups, which provides information on the efficiency of the lighting control.

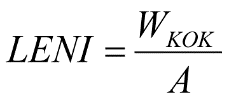

The LENI index expresses the total amount of energy used by a building’s lighting system per square metre each year (kWh/m2/year). It can be calculated by means of Formula 1:

(1), where

(1), where

LENI is the index for the total amount of energy used by the building’s lighting system (kWh/m2/year),

WKOK is the total of amount of energy used for lighting (kWh/year), and

A is the illuminated area (m2).

In addition to the total energy use, the formula factors in the actual period of use. The LENI index can be used to compare the amounts of energy used by lighting systems when the buildings are of different sizes but used for the same purpose.

Analysis of a lighting solution’s energy-efficiency

Photometric analysis

This section introduces various measurements used for evaluating a lighting system’s energy-efficiency. The goal is to arrive at an index value for each measurement, with an average value then calculated for these index values. This gives us an overall index value for the lighting solution, describing its energy-efficiency. The scale for the index values is 1 to 5. As all the necessary data are derived from the results produced by the lighting design software, the index values for the measurements are reliable only if accurate information is available for the premises’ luminaires, surfaces, and luminaire locations.

1) Illuminance (lx)

The minimum requirements set in the SFS-EN 12464-1 standard should be complied with, as doing so has a positive effect on visual performance and comfort. On the other hand, exceeding the level of lighting considered adequate is not recommended, since this can result in glare and increased energy consumption. The illuminance index has a detrimental effect on the overall energy-efficiency index if the minimum level is exceeded to a considerable extent.

2) Uniformity, U0 (Emin/Em)

Exceeding the required uniformity level does not have a significant impact on the lighting system’s energy-efficiency. However, uniformity and energy-efficiency are linked in that if the lighting system features luminaires with narrow light distributions, more luminaires must be installed for achieving the required level of uniformity. This has a direct impact on the installation’s cost. Correspondingly, an adequate level of uniformity is easier to achieve with luminaires that have a wider light distribution and also emit indirect light. The uniformity index lowers the overall energy-efficiency index only if the requirements set in the standard are not met. If the uniformity value is 10% of the value specified in the standard, the index value decreases by 1. The index value decreases with every 10% reduction in uniformity.

3) W / m2 / 100 lx

A lighting system’s energy-efficiency is measured in W / m2 / 100 lx. This index describes the amount of energy required to illuminate a square metre at 100 lx. The value can be derived from the lighting analysis performed with the DIALux software. The W / m2 / 100 lx index value decreases if the target value for the space is exceeded to a considerable extent.

4) LENI index

The control system has a significant impact on the lighting solution’s energy-efficiency. It affects both the lighting efficacy at any given time and the period when the lights are on. These are proportional to the lighting solution’s energy-efficiency. Lighting control is assessed by means of the LENI index because this value takes into account the amount of time the space is in use, the availability of daylight, and lighting control properties.

The index value is determined by calculating the LENI value. For this calculation, the following information is required: the premises’ usage time, the usage rate (from D5), the control factor (from D5), and the W / m2 / 100 lx value. The lower the LENI value, the better the index value for this metric. When one is assessing the controllability of the lighting system, it is important to remember that having a lighting control system is not beneficial for all premises, and for premises where one isn’t suitable, the LENI value should be excluded or the overall index value should otherwise not suffer because of it.

5) UGR index

As for UGR, the index value is 5 when the UGR value is equal to or below the maximum value specified in the standard. For each point above the maximum value, the index value decreases by 1. If the UGR index output by the lighting design program exceeds the maximum value by five or more units, 0 is designated as the index value.

Technical and economic analysis

1) The payback period and prescurrent value of the investment

2) Energy consumption

3) CO2 emissions