Automation detects and isolates faults in overhead line networks

Power outages are reduced and shortened by minimizing the fault area and disconnecting it quickly from the grid. Lappeenrannan Energiaverkot uses Ensto's network automation to improve its customers' electricity quality.

Large cable reels on the roadside have become part of the Finnish landscape as network companies build a weatherproof distribution network by changing their overhead lines to underground cables. The workload and annual investments are substantial to achieve the reliability requirements set by the regulator on time. Cabling of urban areas is now well in progress and the focus is already changing on rural overhead networks. Long branches of lines, often in difficult terrain with lakes and rocky hills, force to look for alternatives to cabling. The solution can be found in the overhead line network automation.

Faster way than removing on the roadsides or cabling

“Widening and clearing right-of-ways or removing overhead lines along the roadsides can be as time consuming and expensive as underground cabling. Instead, network automation such as reclosers and load-brake switches are quick to implement,” says Antti Lintunen, Operations Manager at Lappeenrannan Energiaverkot Oy.

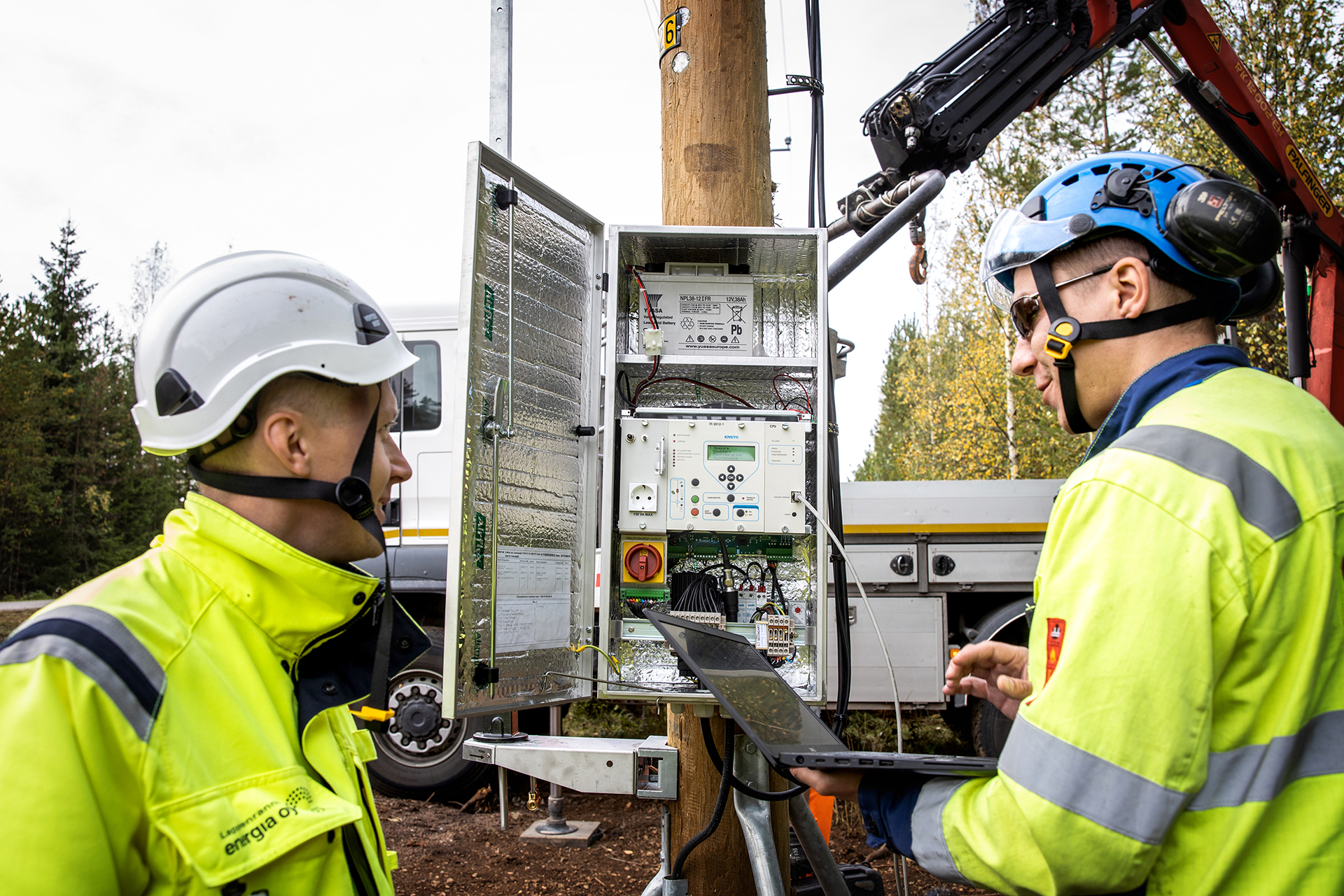

In addition to Lappeenranta, a city in southeastern Finland, the company's distribution area covers three municipalities with densely populated areas. It also has wide rural and lake-side areas with a large number of second homes. There is more than 6,000 kilometers of electricity network to maintain, which means more than 100 meters per customer on average. Lappeenrannan Energiaverkot has recently installed automatic, pole mounted reclosers Ensto Smartclosers. They detect a fault behind them, isolate the faulty network section and act as an independent protection device.

– With Smartclosers, we have created new protection zones for one long and fault-sensitive overhead line that splits into two parts. Now, disruptions on one branch no longer affect customers on the other branch, Lintunen says.

Automatic isolation to restore supply

The most recently applied automation solution to enhance reliability is the Ensto Auguste load-break switch. It was placed on a rural overhead outlet, which is longer than average and very vulnerable to failures. There is already a remote-controlled secondary substation in the middle of the line, but the new load-brake switch was installed to divide the end of the line into even smaller sections. It is also known that the line will not be repaired or moved to the roadside in near future.

– I think the biggest benefit of Auguste is the ability to detect earth and short circuit fault currents, which speeds up finding of the fault location. With the help of automatic fault isolation function, the defective part of the network can be disconnected, and the power restored immediately without intervention of personnel, says Antti Lintunen.

– Placing the device in the grid is easy, since it has no need for separate power supply. Also, it is maintenance free, which will reduce costs in the future.

Standalone devices work together

Auguste’s short-circuit and earth-fault protection are based on measured currents, for which limit values can be set. When they are exceeded, the automatic sectionalizing function is activated and SCADA receives an alarm. The fault current is interrupted by a front recloser such as Smartcloser, giving time for Auguste load-brake switch to automatically separate the faulty section momentarily. If the fault still exists after reclosing, the recloser gives another chance for the switch to separate it permanently. After the second reconnection by recloser the supply is restored to the healthy part of the network.

Interoperability requires the equipment to be set, tested and connected to the SCADA system. Ensto offers this as a commissioning service provided by partner Enerke Oy. In this way, the network operator only needs to organize the mechanical installation of the device, as was the case in Lappeenranta.

– I can recommend the commissioning service, as Ensto can offer a trained professional who knows the equipment, says Lintunen.

Maintenance-free means money saved

– The Lappeenranta case is a model example of a fast and cost-effective way to increase the reliability of the overhead line. It represents today's network automation, which shortens the power outage time and reduces maintenance costs, says Jukka Kokkonen, Sales Manager for Ensto Eastern Finland.

– Also, in many countries there are tens of thousands of kilometers fault-sensitive overhead line, which could be easily and economically automated the same way, he says.

The technology exists and is reliable even under extreme conditions. As evidence of that, more than 10,000 Ensto Auguste load-break switches have already been installed worldwide.