Ensto puts itself to the test in its Porvoo laboratory

These are busy times for Ensto’s laboratory in its network construction business unit in Porvoo. Approximately 100 of the unit’s products are subject to product certification and additionally, other products are subject to type tests. Type tests are usually done for a product at least once every ten years, or when a parts supplier or mould is changed, for example.

Why are products certified – and what is accreditation?

Product certification is required in many countries, because customers want to know that an impartial, trustworthy body has confirmed that a product meets all the applicable requirements. In other words, the accredited certification body acts as a third party and verifies that the products actually meet the required standards. Usually, this also involves inspections to ensure that the manufacturing process produced consistently high-quality products. Most of the products are tested in Ensto’s own laboratory. Only a few products or product families are tested in external, ILAC-accredited laboratories.

Because so many products need to be tested, the resources of outside laboratories are limited, and the testing costs are high, the Porvoo laboratory decided to apply for ILAC accreditation. This was in autumn 2014. ILAC accreditation ensures that testing results are acceptable worldwide, making repeat testing in each country unnecessary. The Finnish Accreditation Service (FINAS) audits the Porvoo laboratory once a year, and the laboratory conducts a couple of annual internal audits, as well.

Creating jobs as well as quality

The Porvoo was required to take some corrective measures, and once these were taken care of the accreditation was granted quickly, at the end of 2014. The accreditation process ran so smoothly thanks to the Porvoo laboratory’s several strengths:

- A highly trained and knowledgeable workforce

- Many years of practical experience in the relevant sorts of testing

- High-quality, modern equipment capacity

- A long-standing practice of documenting the operating system.

In addition, a couple of years earlier the laboratory had prepared its own quality manual, which already took account of the ISO 17025 standard. This also required practical measures. Standard ISO 17025 is based on the ISO 9001 standard, but has much tougher requirements concerning the competence of personnel, testing equipment, facilities and operations.

Maintaining a quality system is labour-intensive, but it has made laboratory work more systematic, and so also more efficient and trustworthy. It has also helped the lab staff to further develop their skills.

Why would Ensto do tests in its own laboratory?

Ensto has invested in its own laboratory for years, and will continue to do so. Having a lab of its own benefits a company in several ways:

- Independence in test scheduling

- Easier to obtain more information about the properties of products

- Easier to eliminate the effects of faulty testing

- Easier to conduct more product development testing

- Staff competence develops in laboratory work, product development and product management

- Testing usually more cost-effective.

Product certification independently or with partners

Maintaining product certification with existing product quantities employs one to three full-time staff, depending on the size of the repeat testing backlog and on whether sample testing or type testing are being carried out. The lab currently conducts an average of 20 repeat tests a year. New products are continually being developed, and so the number of products to be certified is growing all the time.

The Ensto Utility Networks laboratory has a cooperation agreement with two product certification bodies elsewhere in Europe. They have audited the lab, and if necessary they will conduct follow-up audits every few years. Nowadays they largely rely on the annual FINAS audit, which means that if the agreed tests remain in use in our accredited area, the agreements will also remain in force.

In practice, we carry out the testing and prepare the test reports ourselves, in our own laboratory. After the test reports have been completed, they are sent to the certification authority for approval. If the authority approves the testing, the product certificate can be issued.

Which comes first – type testing or certification?

Certification bodies have a slightly different practice regarding how long a product certificate is valid, and also regarding the renewal procedure (in the case of a product whose parts and production method have not changed over time). The period of validity varies between three and five years. For a new product, of course, complete type testing must be carried out first. After this, it will have been agreed with a certain operator, for example, that when the certificate expires five years later it can be renewed provided that the product passes the sample test. After the five years have passed and the certificate becomes out of date, to renew the certificate the entire type testing must be carried out again. In this way, the certification body can ensure that the product continues to meet the requirements and at the same time verify that the applicable standards have not changed.

Not one test, but many: an example

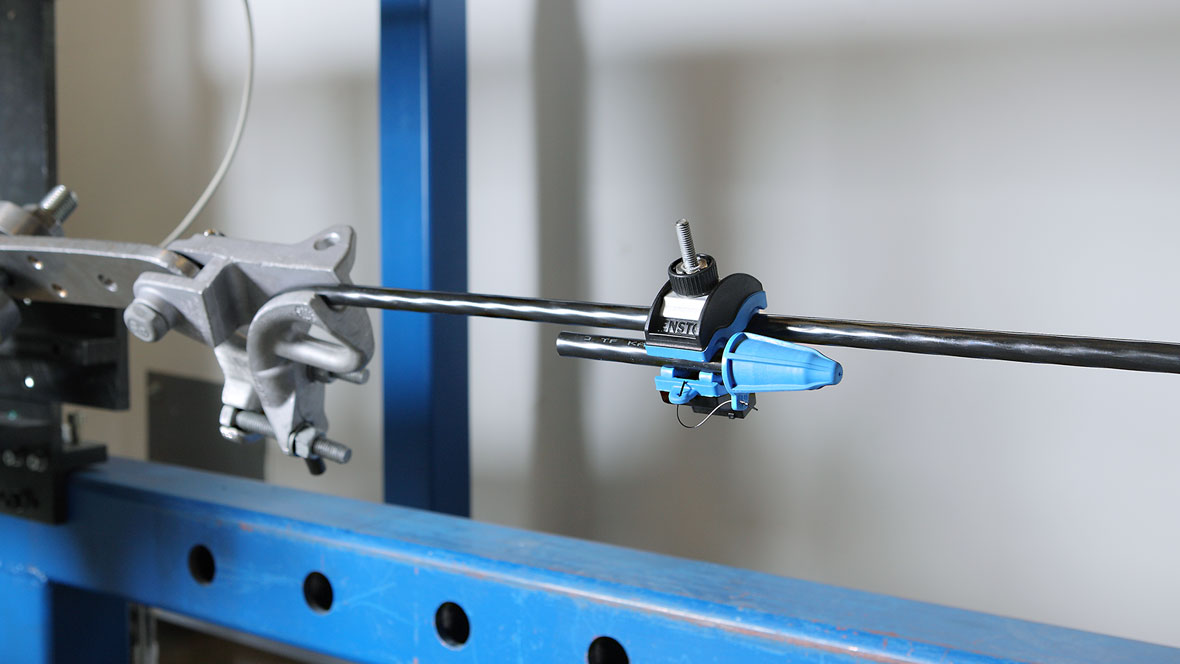

There is certainly a lot of testing and coordination to be done, since the different tests for each product actually consist of multiple individualised tests. For instance, the type test for the SLIW52 waterproof insulation piercing connector consists of the following tests:

- Visual inspection

- Material and dimensional inspection

- Verification of product label permanence

- Voltage test immersed in water

- Corrosion test

- Weather-aging test

- Main line tension test

- Branch line tension test

- Bolt tightening test

- Cold installation test

- Torque screw shear test

- Impact test in cold conditions

- Electrical aging test

The sample test for the same connector consists of the following tests:

- Visual inspection

- Material and dimensional inspection

- Verification of product label permanence

- Voltage test immersed in water

- Main line tension test

- Branch line tension test

- Torque screw shear test

The tests are usually carried out in the conductor range of a connector, on lines of both minimum and maximum cross-sectional area. As is plain to see, the Porvoo lab must keep many things in order!

Additional information and abbreviations:

The scope of the accreditation of Ensto’s Porvoo laboratory is described in the FINAS website (in both Finnish and English):

https://www.finas.fi/toimijat/Sivut/default.aspx#k=ensto

https://www.finas.fi/sites/en/operators/Pages/default.aspx#k=ensto

ILAC: International Laboratory Accreditation co-operation

FINAS: Finnish Accreditation Service (the Finnish national accreditation body)

Member of EA, EAC, ILAC and IAF

Accredits certification bodies, testing and calibration laboratories in Finland

EA: European Co-operation for Accreditation

EAC: European Accreditation for Certification

IAF: International Accreditation Forum

ISO 9001: Quality management systems – Requirements

ISO/IEC 17025: General requirements for the competence of testing and calibration laboratories

Links:

EA: http://www.european-accreditation.org/

ILAC: http://ilac.org/about-ilac/

FINAS: https://www.finas.fi/sites/en/Pages/default.aspx